CNC precision machining is answerable for establishing these prototypes to specific requirements. The system also provides elements for other modes of transportation, like transport vessels, transportation vans, and Other people.

Furthermore, the parts have higher accuracy and close tolerance finishes, so there's no want for secondary processes. This contributes to a lot quicker production moments, rising the workshop’s productivity and effectiveness.

In mass production, CNC machines are used to make substantial portions of identical parts with high precision and consistency. This method is important in industries which include automotive, electronics, and consumer merchandise.

Expense-Effective in Significant Production Runs: CNC machining can incur higher First set up prices; however, its precision and velocity ensure it is Value-effective with time, especially for large production operates.

Due to intensive variety of applications, CNC precision machining calls for a wide range of machinery and equipment. Listed here are the machinery and equipment:

Automobile suppliers have to style prototypes of such CNC machined parts before production as innovations are extra for their recent car revisions.

The shipments spotlight how, In spite of a U.S.-led regime of global restrictions that is definitely Among the most expansive in background, Russia’s protection industry has remained sturdy partly because of regulatory loopholes and lax enforcement.

Numerical machines are programmed by using a set of instructions that go ahead and take sort of letters, figures, and symbols. Punch playing cards are used to ability NC machines. NC Machines include some fundamental factors.

A first-rate illustration of CNC machining in electronics is the metal alloy casing of Apple items such as the Macbook as well as apple iphone. They are designed employing a CNC milling machine and CNC routers. CNC applies not only to your exterior circumstance but will also to The inner factors of consumer electronics solutions.

Musical instruments have to have next-stage craftsmanship and precision. This is because a slight deviation through the intended structure can result in important changes while in the musical harmony from the completed product, properly making it faulty.

CNC machining from the healthcare and medical industry is used for manufacturing health-related provides and swift tooling to create dies for injection molding. Then, the injection molding course of action makes equipment like confront masks.

CNC milling is usually a subtractive manufacturing treatment that makes here use of rotary cutters to eliminate materials from an item. Distinct cutting effects can be reached by various the angle, way, stress, and cutting tool speed.

Advancements in biocompatible materials and 3D printing integration with CNC machines will even more greatly enhance the capabilities of healthcare manufacturing.

Yet another advantage of Nanotech Precision Swiss machining is the opportunity to end complex parts in one setup. Nanotech utilizes very versatile machine tools with approximately ten controlled axis that could machine capabilities from any angle or course, all though protecting Charge of the machined ingredient. Really complex swiss machined parts and factors are popular at Nanotech Precision.

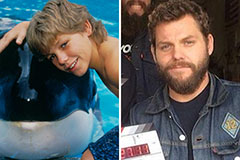

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Batista Then & Now!

Batista Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!